Lutronic: The Lumberg Sister Expands the Feeding Systems Business Unit with a High-Performance Drum Feeder

Schalksmühle, 08.08.2019. Lutronic, set up for international operations in 2016, is specialized in feeding systems for machinery and equipment. In another business unit actuator/sensor wiring solutions with M8 and M12 connectors for automation are offered. The company’s connectivity solutions also include the matching passive distribution boxes. The product range is supplemented by LED machine lights.

It was not until 2018 that Lutronic diversified into the business unit of mechanical engineering, which is also targeting the automation industry: Here, a complete range of feeding systems for machinery and equipment is offered. Developed and manufactured in the mechanical engineering department of the Lumberg Group at the Cloppenburg factory in Germany, which, with around 175 specialists, has so far implemented sophisticated solutions solely for its own production for assembly technology from feeding technology to complete production lines, Lu-tronic undertakes the exclusive marketing of special feeding solutions: From spiral and linear vibratory feeders to centrifugal feeders, bulk hopper conveyors, reel decoilers with a focus on precision and high-speed and, of course, the associated conveyor belts for the transport routes.

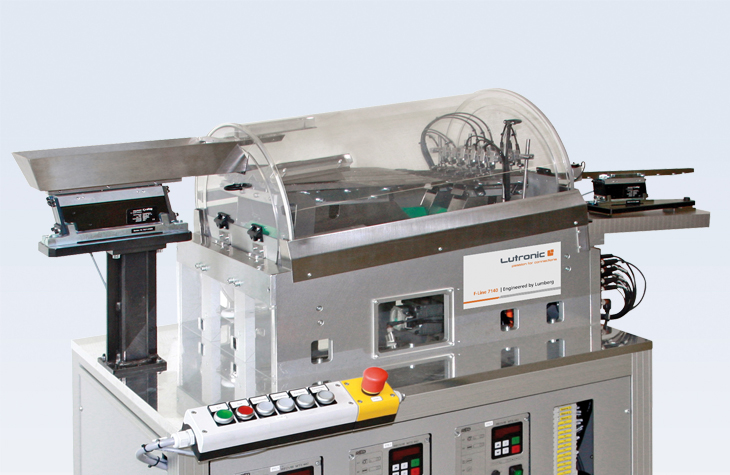

For the first time, the range now includes a powerful drum feeder for small to large output quantities. The drum feeder is a component-specific device for feeding, sorting, separating and aligning small parts in bulk, which at Lutronic is based on a horizontally arranged, permanently rotating drum. The particular strength of the drum feeder is the disentanglement and separation as well as the orderly placing of smaller components with difficult geometries, e.g. compression springs, pins or screws, on one or more linear rails to an assembly line. The rotational speed of the drum and the conveying speed of the integrated longitudinal conveyor are adjusted according to the work piece geometry and desired performance parameters. The feeding unit, which is very compact for its high performance, only requires a 6-bar compressed air connection and a 230 V power supply.

Lutronic’s international team helps with the planning of the feeding periphery around the core process. Lutronic designs and builds tailor-made systems around the customer’s system in the centre. Of course, Lutronic technicians also take care of commissioning, diagnosis and mainte-nance, service packages and documentation – worldwide.

Media Contact:

Lutronic Holding GmbH

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Article as PDF Printable Photo